Treated Rolled Copper Foil

As the world's leading supplier of treated rolled copper foil, we are helping in the advancement of the flexible printed circuit board industry.

JX Group's rolled copper foil products are produced through an intergrated manufacturing system covering from mining of copper ore to smelting and refining, ingot production, rolling, and surface treatment, within the same group.

Thanks to the stable supply and high quality achieved through this integrated system, we have become the world's top supplier of treated rolled copper foil. Also utilizing this integrated system, we are developing and supplying the broadest range of treated rolled

copper foil products to satisfy customer's needs.

RA Product Lineup

| Grade | Type | Features | Purity | Thickness (µm) | ||||

|---|---|---|---|---|---|---|---|---|

| 70 | 35 | 18 | 12 | 9 | ||||

| General | TPC | Standard | Cu: At least 99.9% |

|

||||

| High Functionality | HA | Static Bendability (high flexibility) Low repulsive force | Cu: At least 99.9% Ag: 190 ppm |  |

||||

| HA-V2 | Static Bendability (high flexibility) Low repulsive force Ease of handling | Cu: At least 99.9% Ag: 100 ppm |  |

|||||

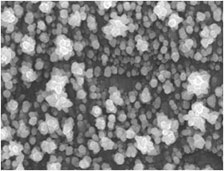

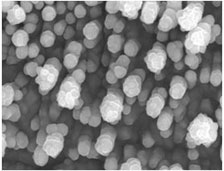

| Grade | Type | Features | Matte Side Roughness (Rz) | Shiny Side Roughness (Rz) | Nodule-Treated Surface SEM Photograph |

|---|---|---|---|---|---|

| General | BHY | Standard | 0.80 µm | 0.75µm |  |

| High Functionality | BHYX | Strong Adhesion | 0.90µm | 0.75µm |  |

Typical Properties

Physical Properties

| Type | IPC Grade | Modulus (GPa) (Resonance method) | Electronical Conductivity (% IACS) | Resistivity (ohm-gram/m²) | |||

|---|---|---|---|---|---|---|---|

| RT | After Annealed (180°C /1h) | ||||||

| MD | TD | MD | TD | ||||

| BHY-T | 8 (LTA-W) | 105 | 120 | 105 | 100 | 100 | 0.154 |

| BHYX-HA | 8 (LTA-W) | 122 | 140 | 76 | 76 | 100 | 0.154 |

Mechanical Properties

| Type | IPC Grade | Hardness (Hv) | Tensile Strength (MPa) | Elongation (%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RT | After Annealed (180°C /1h) | RT | at 180°C | After Annealed (180°C /1h) | RT | at 180°C | After Annealed (180°C /1h) | ||||||||

| Vickers | MD | TD | MD | TD | MD | TD | MD | TD | MD | TD | MD | TD | |||

| BHY-T | 8 (LTA-W) | 106 | 58 | 440 | 420 | 193 | 157 | 210 | 160 | 1 | 1 | 2 | 2 | 10 | 6 |

| BHYX-HA | 8 (LTA-W) | 100 | 40 | 500 | 510 | 211 | 89 | 145 | 120 | 2 | 3 | 1 | 1 | 8 | 4 |

Surface Roughness

| Type | IPC Grade | Roughness (µm) | |||

|---|---|---|---|---|---|

| Shiny Side | Matte Side | ||||

| Ra | Rz | Ra | Rz | ||

| BHY-T | 8 (LTA-W) | 0.11 | 0.75 | 0.12 | 0.80 |

| BHYX-HA | 8 (LTA-W) | 0.11 | 0.75 | 0.13 | 0.90 |

HA and HA-V2 Foils

- Have large crystal grain and uniform crystal orientation which dramatically improve the flexibility, vibration resistance and other properties.

- High functionality treated rolled copper foil realizing outstanding flexibility.

- Dramatic improvement in vibration resistance.

- Low repulsive force for high pliability.

- Excellent cube orientation.

Surface Treatment

- Fine surface treatment for very low surface roughness.

- Strong adhesion performance.

- Very low roughness is achieved also on the matte side.

- Outstanding high-frequency characteristics, visibility, and fine patterning.